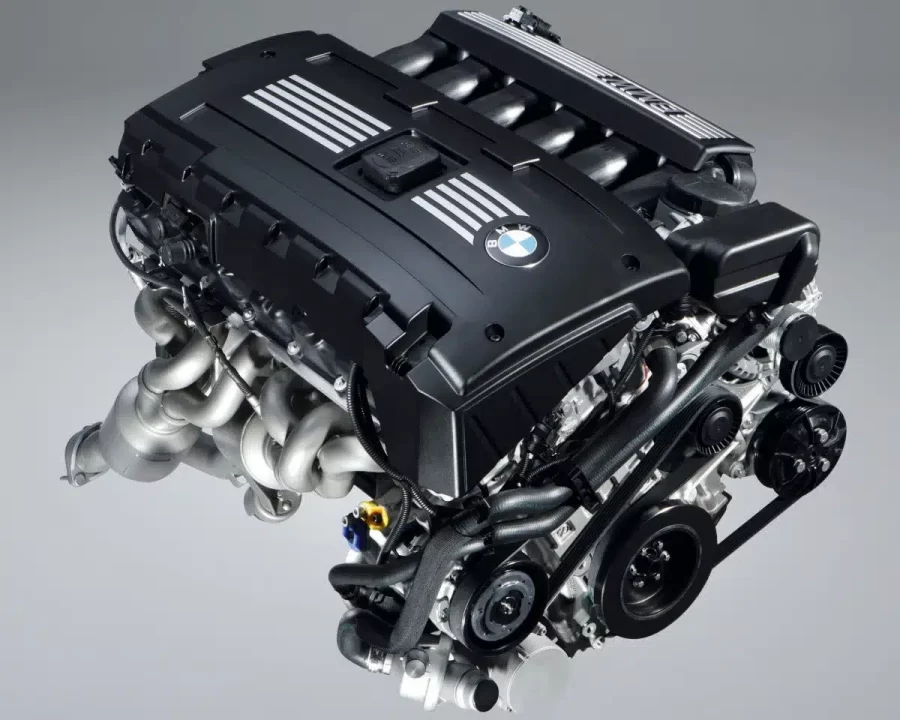

BMW’s 3 and 5 Series models, which were produced between 2005 and 2010, had N53 engines under the hood. These are excellent powerplants that met the requirements of environmental friendliness, supported the sporty style of the brand and had quite good reliability indicators.

These powertrains are quite common, which makes it much easier to repair them as well, due to the general accessibility to the main components of the powertrain. We will talk in more detail below. The first engine came off the assembly line in 2004. The whole line was developed on the basis of the N52 series. But there are several significant modifications, which increased the injectivity and performance of the N53 series. Motorists emphasized the performance of the engine, which is why it was decided to use direct fuel injection systems in the combustion chamber. The system, which changed the height of valve lift turned out to be quite ambiguous. Well-known automobile magazines spoke negatively about it. Therefore, BMW motorists decided to remove this system. In order for the engine to meet the new requirements of environmental friendliness and performance, the piston system and cylinder head were changed almost to zero. The cherry on the cake is the application of a completely new engine management system SiemensMSD81.

Engine specifications N53B30UL

| Power, hp. | 218 |

| Fuel type | Gasoline |

| Volume, cm*3 | 2996 |

| Maximum torque, N*m (kg*m) at rpm. | 270 (28) / 4200 |

| Fuel consumption, l/100 km | 7.6 – 8.9 |

| Engine type | In-line, 6-cylinder |

| Number of valves per cylinder | 4 |

| Maximum power, hp (kW) at rpm. | 218 (160) / 6100 |

| Blower | No |

Advantages

Amusingly, BMW at first did not risk mass-marketing the first direct-injection N53 engine in all markets due to fears of intense coke formation at the injectors. At the same time, the design of the BMW-SIEMENS injectors is fundamentally different from competitors using the coking-prone “open” orifice. BMW injectors “atomize” by means of opening the valve, which represents the pointed top of the pyramid – this atomization “cleans” the valve seat by the very process of atomization, quite similar to the way the inlet channels of valves on engines with conventional injection system are cleaned. But there is no cure for this disease of all direct injection engines.

Disadvantages

When it comes to reliability. The N53 engine lineup has been well received by the public and drivers alike. But nothing is perfect, so there are several features of the engine that should definitely be considered when using this power unit. The first issue that arises when operating an internal combustion engine is the quality of the fuel being filled. You should not refuel at the first gas station you come across. Since dirt and debris in low-quality fuel can lead to failure of the entire system. If there are problems with starting the engine, it is necessary to pay attention to the performance of the ignition coils. In addition, problems may occur with the DoubleVANOS and Valvetronic systems.

Technical specifications

Let’s talk about the technical specifications. The exact volume of the engine is 2996 cubic centimeters. The maximum power that the powertrain can develop is 218 horsepower. The value of maximum torque is in the range of 270 – 280 Newtons per meter, when the engine reaches 4200 rpm. At the same time, the maximum power we indicated at the value of 218 horsepower is reached by the powertrain when cranked up to 6100 rpm. Despite the fact that the manufacturer recommends using fuel with an octane number of 92, in order for the powertrain to not have problems with the fuel system, it is necessary to fill gasoline with an octane number of 95. Fuel consumption in the mixed cycle for every 100 km is about 9 liters. As for the engine type, it is an in-line, six-cylinder power unit. From the technical innovations it is also worth noting the digital system for engine management, DoubleVanos system, which is responsible for adjusting the timing. And the Valvetronic system, which is responsible for controlling the operation of the valves. Continuing with the technical characteristics, the engine has 4 valves per cylinder. There is no supercharger in all modifications of the N53. While the start-stop system acts as an option. The average life of the engine is about 300-350 thousand kilometers. But, if you maintain the engine properly, use fuels and lubricants that are specified in the technical passport to the internal combustion engine, it is quite possible to increase the resource of more than 500,000 km.

Features

In this powertrain, the variable camshaft timing system used by BMW on various automobile gasoline engines since 1992 has changed significantly. The name is an abbreviation of the German words for variable camshaft timing : variable nocken wellen steuerung.

The original version was used exclusively on the intake camshaft, while later “DoubleVANOS” systems are used on both intake and exhaust camshafts. Since 2001, VANOS is often used in conjunction with a variable valve lift system. VANOS is a variable valve timing system that changes valve timing by moving the position of the camshafts relative to the drive train. The relative synchronization between the intake and exhaust valves is changed.

At lower engine speeds, the camshaft position moves, so the valves open later, as this improves idle quality and ensures smooth power production. When engine speed increases, the valves open earlier: this increases torque, reduces fuel consumption and lowers emissions. At high engine speeds, the valves open later, because this provides full power.

The second-generation dual VANOS system regulates the synchronization of the intake and exhaust camshafts with infinitely variable adjustment depending on engine speed and throttle opening.

The Valvetronic system, BMW’s variable valve lift system, which combines with variable timing to phase the intake valve, has also been significantly refined. Bavaria Motors claims it improves fuel economy and emissions, and negates the need to develop a new throttle linkage with regular use. First introduced by BMW on the 316ticompact in 2001,Valvetronic has been added to many BMW engines. The first application of this technology in a turbocharged engine was the N55 engine.

0 Comments